DIAMONIQ

Profile

- Programme: Horizon Europe, EIC Accelerator Challenges

- Funding amount: 2.5 million euros for Bavaria

- Funding period: 01/2024-12/2025

- Beneficiary company: Quantum Diamonds GmbH, Kevin Berghoff

- Internet: www.quantumdiamonds.de

EU project DIAMONIQ: Development of an innovative microscopy technology for quality control in the semiconductor industry

The continuing miniaturisation of components in the semiconductor industry is driving technological innovation. However, with increasing miniaturisation, it is becoming increasingly difficult to detect chip defects during the manufacturing process. Conventional methods are reaching their limits. As part of the EU project DIAMONIQ, Munich-based Quantum Diamonds GmbH is working on a novel microscopy technology to solve this problem.

Semiconductors form the basis of all modern electronic devices such as computers, smartphones and televisions. The ongoing miniaturisation of these components is leading to constant technological progress, but also to the increasing complexity of semiconductor chips. Traditional quality control methods, such as thermal imaging or voltage measurements, are no longer sufficient to detect chip defects during the manufacturing process. In addition, previous techniques always had to compromise between speed and image quality, which was time consuming and costly.

Inefficient manufacturing processes can lead to reject rates of up to 20%

Inefficient manufacturing processes can result in a scrap rate of up to 20 per cent, which can mean losses of up to €140 million per year for a single factory. Effective quality assurance during the manufacturing process is therefore crucial.

The solution lies in quantum sensing. These technologies enable precise measurements of quantities such as acceleration, rotation, magnetic fields and gravity with unprecedented accuracy and sensitivity. Quantum sensors have the potential to outperform conventional sensors in a wide range of applications, including navigation, geophysics, medicine, aerospace and materials testing.

New, innovative microscopy technique from Quantum Diamonds

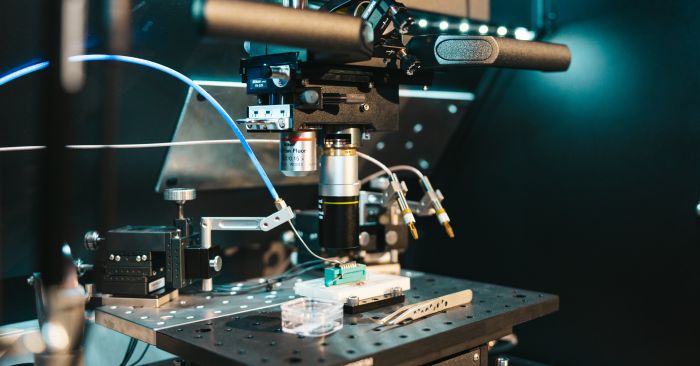

Quantum Diamonds has therefore developed a microscopy technique using diamond-based quantum sensor technology that can detect the tiniest magnetic field changes in defective chips.Unlike other methods, Quantum Diamonds' solution operates at room temperature, has long coherence times and does not require shielding from the Earth's magnetic field. To measure changes in the magnetic fields in the sample, the diamonds are optically activated - so changes in their brightness can be observed. This method enables magnetometry (a method of measuring the Earth's magnetic field or the magnetic properties of materials) with exceptional spatial resolution (less than 100 nanometres), fast measurement times (less than 1 minute) and a large field of view (less than 50 micrometres). The solution includes proprietary optics and software that can be easily used in industrial applications.

"Our technology has the potential to solve existing problems in various industries, including the semiconductor industry, where conventional sensors are reaching their limits. Our sensors can detect tiny defects and thus significantly improve the efficiency of semiconductor production," says Kevin Berghoff, CEO of Quantum Diamonds GmbH.

EUR 2.5 million raised for the next strategic step with the help of BayFOR

Quantum Diamonds GmbH is a Bavarian high-tech company developing highly innovative sensor technologies. Quantum Diamonds is one of 172 start-ups from all over Europe that made it through the highly competitive application process in 2023 and convinced the jury in Brussels. The company intends to use the EU funding to bring its technology to market by 2026.

As an EEN partner specialising in EU funding, the Bavarian Research Alliance (BayFOR) helped Quantum Diamonds to successfully apply for the highly competitive European "EIC Accelerator Challenges" funding. The EIC Accelerator funding instrument is aimed exclusively at innovative, internationally oriented SMEs and start-ups with disruptive ideas and growth potential and helps them to develop concrete and high-risk innovations to market maturity. The application process consists of three steps:

Stage 1: Short application

Stage 2: Full application

Stage 3: Interview (pitch) in front of the jury in Brussels

BayFOR supported Quantum Diamonds GmbH with intensive pitch training in preparation for the interview with the jury in Brussels. The successful cooperation between Quantum Diamonds and BayFOR underlines the importance of long-term and professional support for start-ups by the EEN partners - in this case by BayFOR for funding in the field of innovation and technology development.

BayFOR@Work

"BayFOR offered us tailor-made pitch training and gave us valuable advice on how to improve our performance in front of the jury in Brussels. We worked closely together to identify Quantum Diamonds' strengths in order to present them in the best possible way. This enabled us to present our best side to the jury and gain their confidence.“

Kevin Berghoff, Quantum Diamonds GmbH

Contact

Contact at BayFOR

Natalia García Mozo

Head of Unit SME Advisory Services

Phone: +49 89 9901888-171

Email: mozo@no-spam-pleasebayfor.org