13/07/2022

EU project InShaPe – Next innovation leap in metal-based additive manufacturing

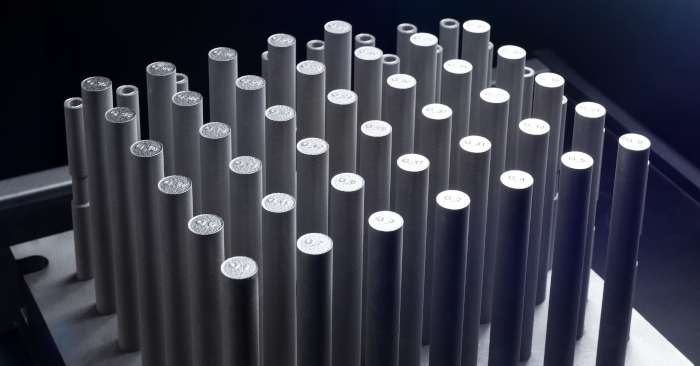

Munich, Germany – In many industrial sectors, such as in the automotive industry, in aerospace or in the energy sector, the demand for special metal components that are light and have a high strength is increasing. Modern gas turbines, for example, require extremely stable and at the same time lightweight heat shields. An important manufacturing process for this is the powder-bed fusion process of metals using laser beam (PBF-LB/M). Depending on the application, the process is not yet always competitive compared with conventional production in terms of unit costs. The research and innovation project InShaPe, funded by the EU with EUR 6.8 million, aims to make a decisive contribution to the further development of the technology. Under the coordination of the Technical University of Munich (TUM), here the Professorship of Laser-based Additive Manufacturing, ten partners from seven countries are working together on the project.

![[Translate to Englisch:] [Translate to Englisch:] BayFOR Circular Flooring Logo](/fileadmin/user_upload/BayFOR-bilder/presse/pressemitteilungen/BayFOR-circular-flooring-logo-l.png)

![[Translate to Englisch:] EU projekt SMHYLES logo](/fileadmin/user_upload/BayFOR-bilder/presse/pressemitteilungen/BayFOR-smhyles-logo-l.jpg)

![[Translate to Englisch:] sunliquid®-Anlage in Podari bei Nacht](/fileadmin/user_upload/BayFOR-bilder/presse/pressemitteilungen/BayFOR-lignoflag-sunliquid-night-l.png)

![[Translate to Englisch:] BayFOR TwinVECTOR](/fileadmin/user_upload/BayFOR-bilder/presse/BayFOR-twinvector-battery.jpg)

![[Translate to Englisch:] BayFOR IntelliMan](/fileadmin/user_upload/BayFOR-bilder/presse/BayFOR-intelliman-key-visual-1.jpeg)